5 Whys Technique

What is the 5 Whys technique?

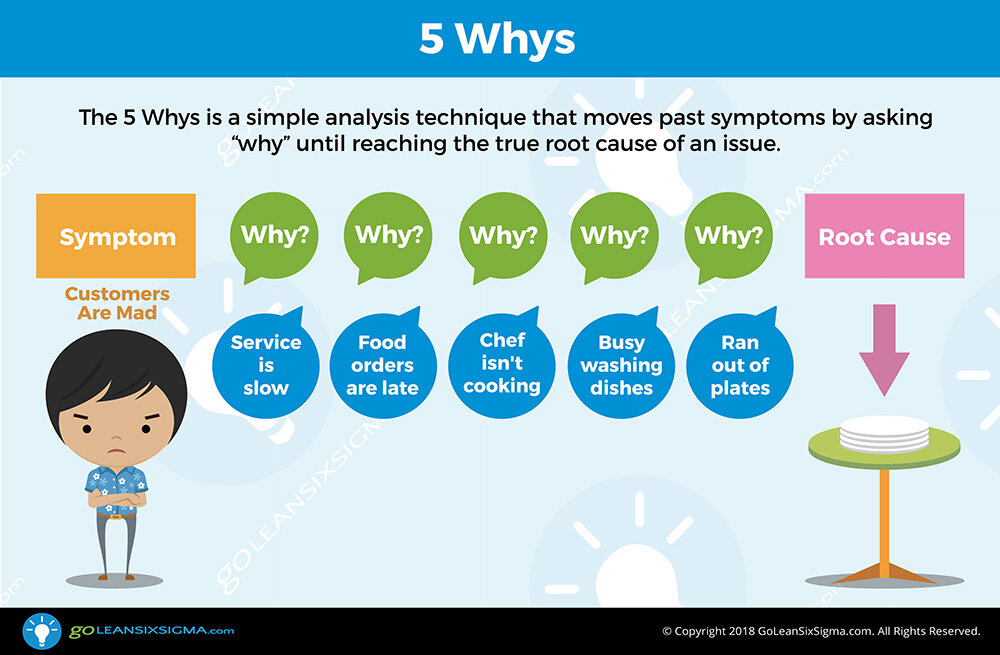

This is a simple but powerful tool for cutting quickly through the outward symptoms of a problem to reveal its underlying causes, so that you can deal with it once and for all.

Origins of the 5 Whys Technique

Sakichi Toyoda, the Japanese industrialist, inventor, and founder of Toyota Industries, developed the 5 Whys technique in the 1930s. It became popular in the 1970s, and Toyota still uses it to solve problems today.

Toyota has a "go and see" philosophy. This means that its decision making is based on an in-depth understanding of what is actually happening on the shop floor, rather than on what someone in an office thinks might be happening.

The 5 Whys technique is true to this tradition, and it is most effective when the answers come from people who have hands-on experience of the process or problem in question.

The method is remarkably simple: when a problem occurs, you drill down to its root cause by asking "Why?" five times. Then, when a counter-measure becomes apparent, you follow it through to prevent the issue from recurring.

Note that the 5 Whys uses "counter-measures," rather than "solutions." A counter-measure is an action or set of actions that seeks to prevent the problem from arising again, while a solution may just seek to deal with the symptom. As such, counter-measures are more robust, and will more likely prevent the problem from recurring.

When to use a 5 Whys analysis

You can use 5 Whys for troubleshooting, quality improvement, and problem solving, but it is most effective when used to resolve simple or moderately difficult problems. Complex problems may benefit from a more detailed approach, although using 5 Whys will still give you useful insights.

This simple technique can often direct you quickly to the root cause of a problem. So, whenever a system or process is not working properly, give it a try.

How to Use the 5 Whys

The model follows a very simple seven-step process:

1. Assemble a Team

Gather together people who are familiar with the specifics of the problem, and with the process that you are trying to fix. Include someone to act as a facilitator, who can keep the team focused on identifying effective counter-measures.

2. Define the Problem

If you can, observe the problem in action. Discuss it with your team and write a brief, clear problem statement that you all agree on. For example, "Team A isn't meeting its response time targets" or "Software release B resulted in too many rollback failures."

Then, write your statement on a whiteboard or sticky note, leaving enough space around it to add your answers to the repeated question, "Why?"

3. Ask the First "Why?"

Ask your team why the problem is occurring. (For example, "Why isn't Team A meeting its response time targets?")

Asking "Why?" sounds simple, but answering it requires serious thought. Search for answers that are grounded in fact: they must be accounts of things that have actually happened, not guesses at what might have happened.

This prevents 5 Whys from becoming just a process of deductive reasoning, which can generate a large number of possible causes and, sometimes, create more confusion as you chase down hypothetical problems.

Your team members may come up with one obvious reason why, or several plausible ones. Record their answers as succinct phrases, rather than as single words or lengthy statements, and write them below (or beside) your problem statement. For example, saying "volume of calls is too high" is better than a vague "overloaded."

4. Ask "Why?" Four More Times

For each of the answers that you generated in Step 3, ask four further "whys" in succession. Each time frame the question in response to the answer you have just recorded.

5. Know When to Stop

You will know that you have revealed the root cause of the problem when asking "why" produces no more useful responses, and you can go no further. An appropriate counter-measure or process change should then become evident.

6. Address the Root Cause

Now that you have identified at least one root cause, you need to discuss and agree on the counter-measures that will prevent the problem from recurring.

7. Monitor Your Measures

Keep a close watch on how effectively your counter-measures eliminate or minimise the initial problem. You may need to amend them or replace them entirely. If this happens, it is a good idea to repeat the 5 Whys process to ensure that you have identified the correct root cause.